Scanning, Optimization and Process Control for Sawmills

Irmach’s advanced scanning, optimization and process control systems are designed to automate and improve many functions that were traditionally manual in sawmill operations, introducing greater precision and intelligence throughout the timber transformation process.

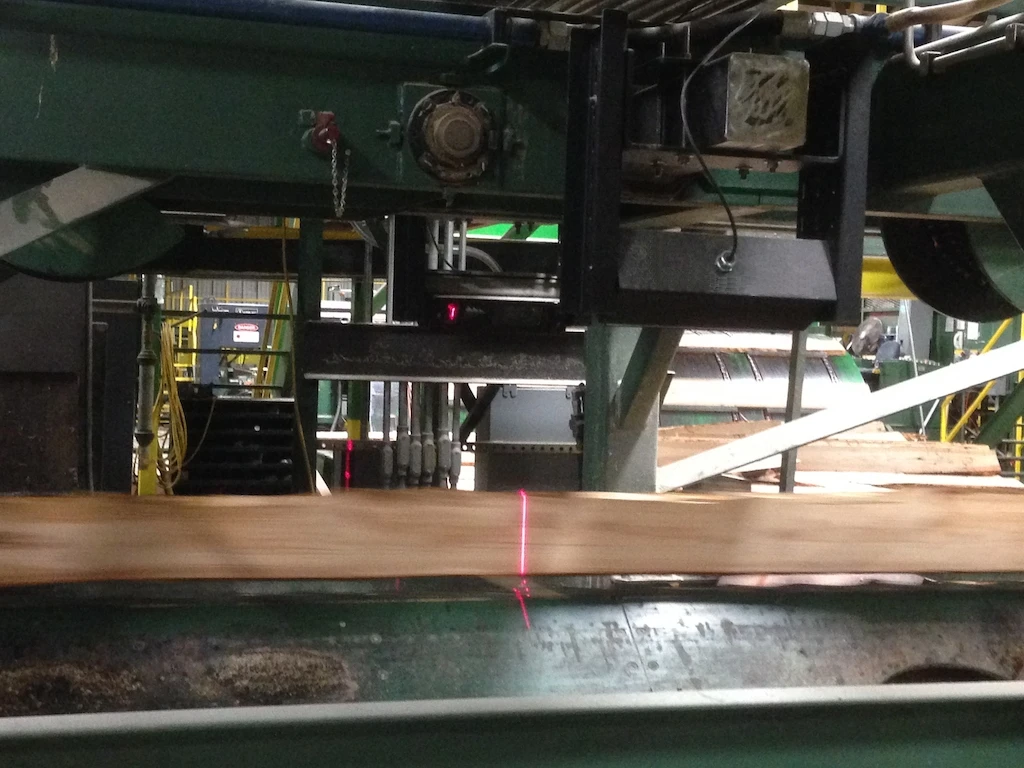

Each log or board is scanned both before and after the cutting phase. Pre-cut scanning enables the optimizer to generate the ideal cutting plan, locate the current position of the piece, and define the precise cutting coordinates. Post-cut scanning checks the actual result, allowing automatic classification by dimensions or detected defects.

This process can be implemented as a modular system, focusing only on cut optimization or on dimensional classification such as length, width or thickness.

This technology is already successfully installed in several sawmills, where it has proven its efficiency, reliability and productivity gains.

Irmach’s solutions are fully compatible with both its own machines and third-party equipment, allowing sawmills to modernise their existing setups without needing to replace the entire line. With the necessary adaptations, integration is seamless and cost-effective.