Description

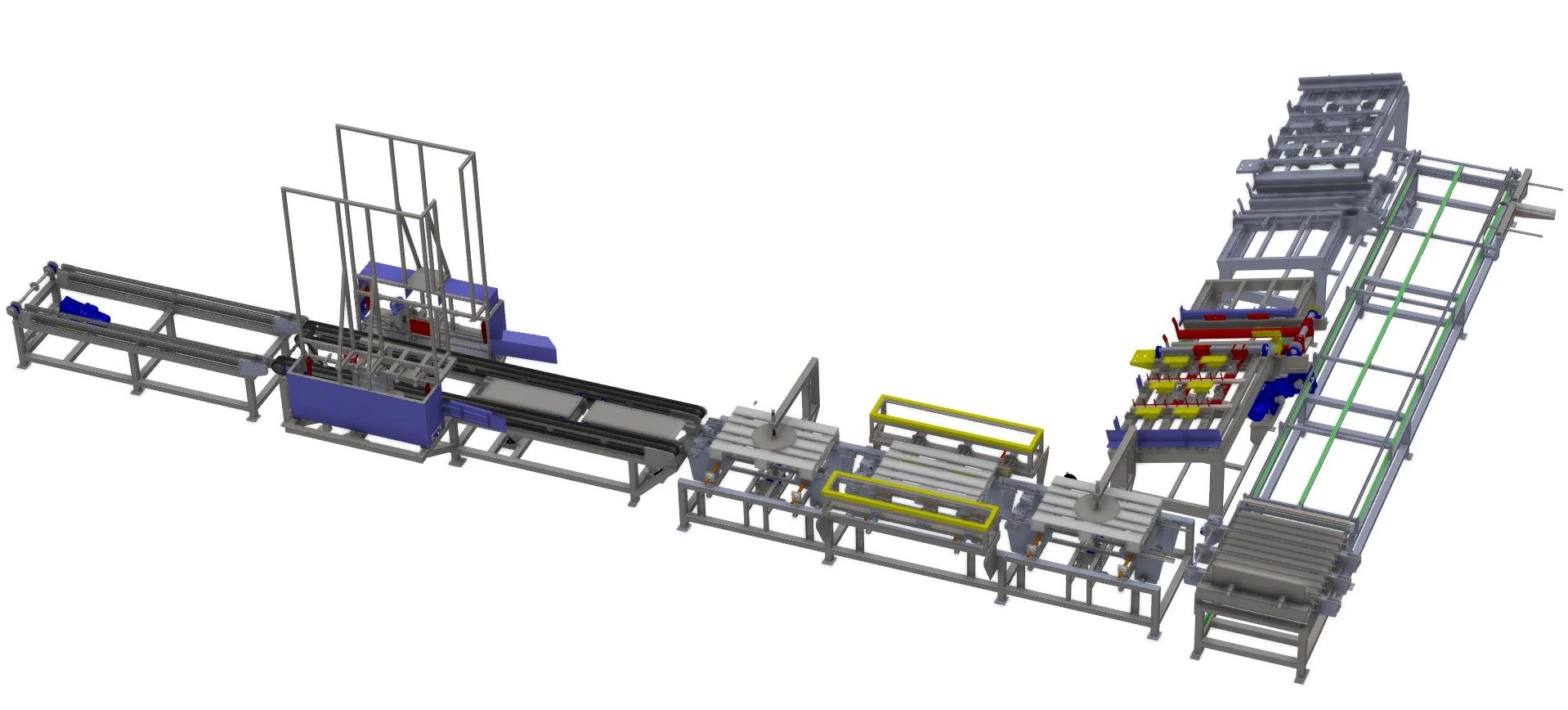

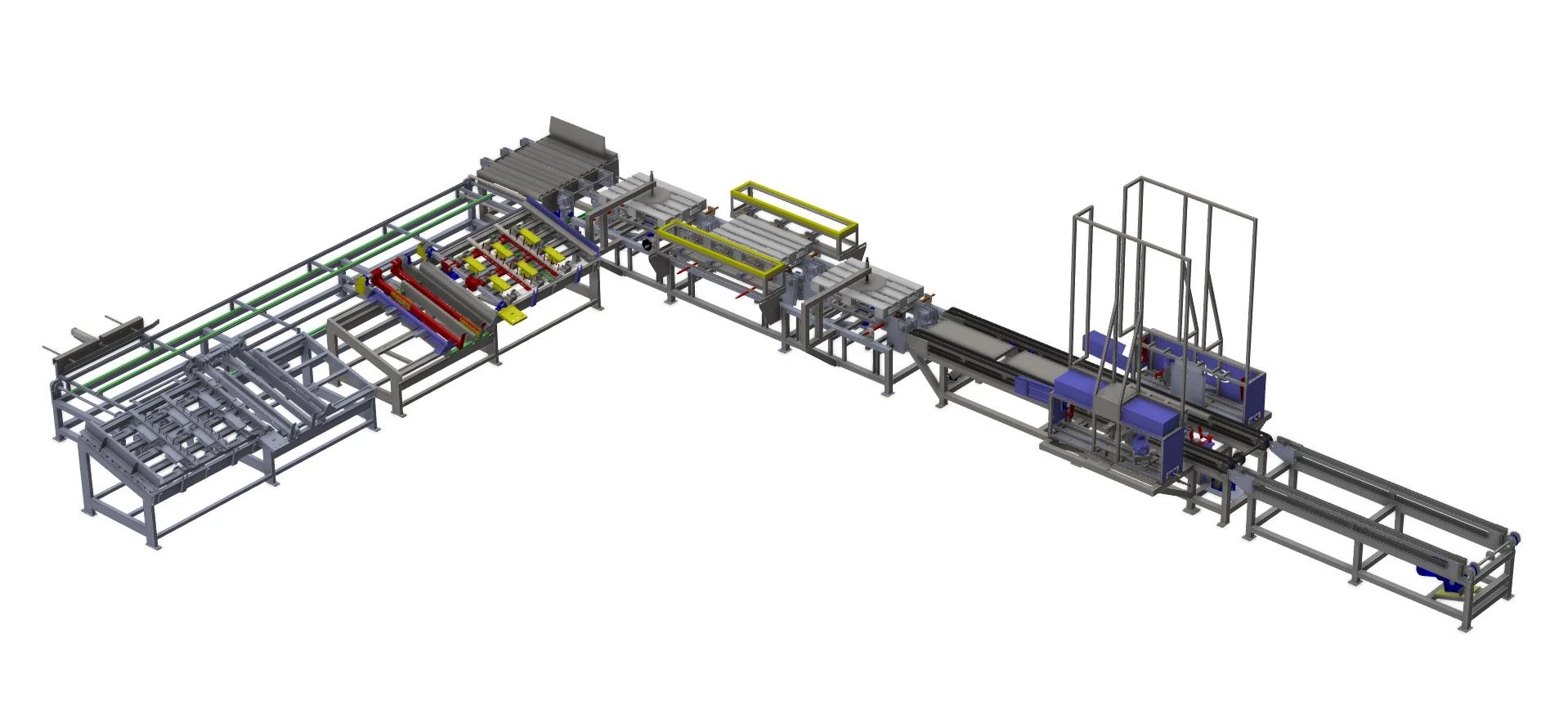

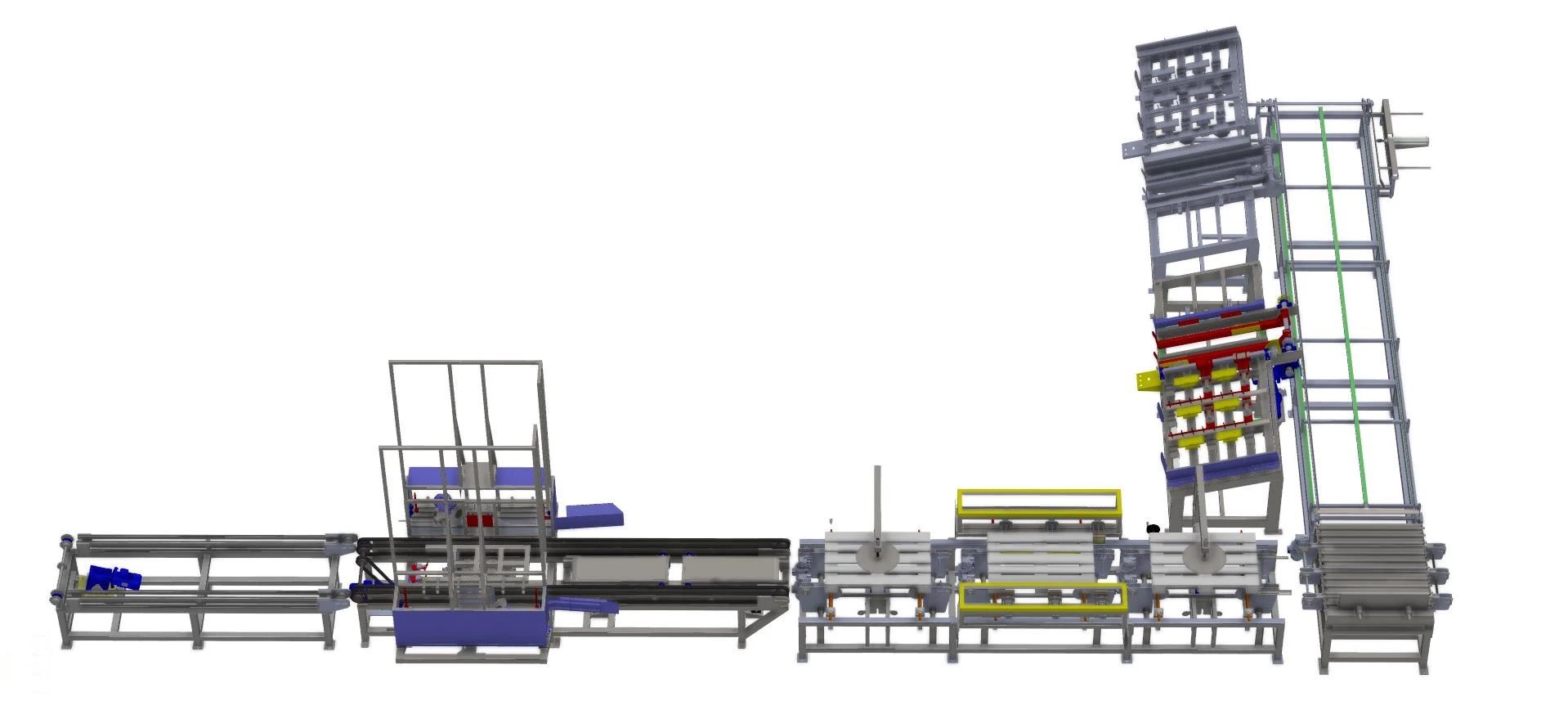

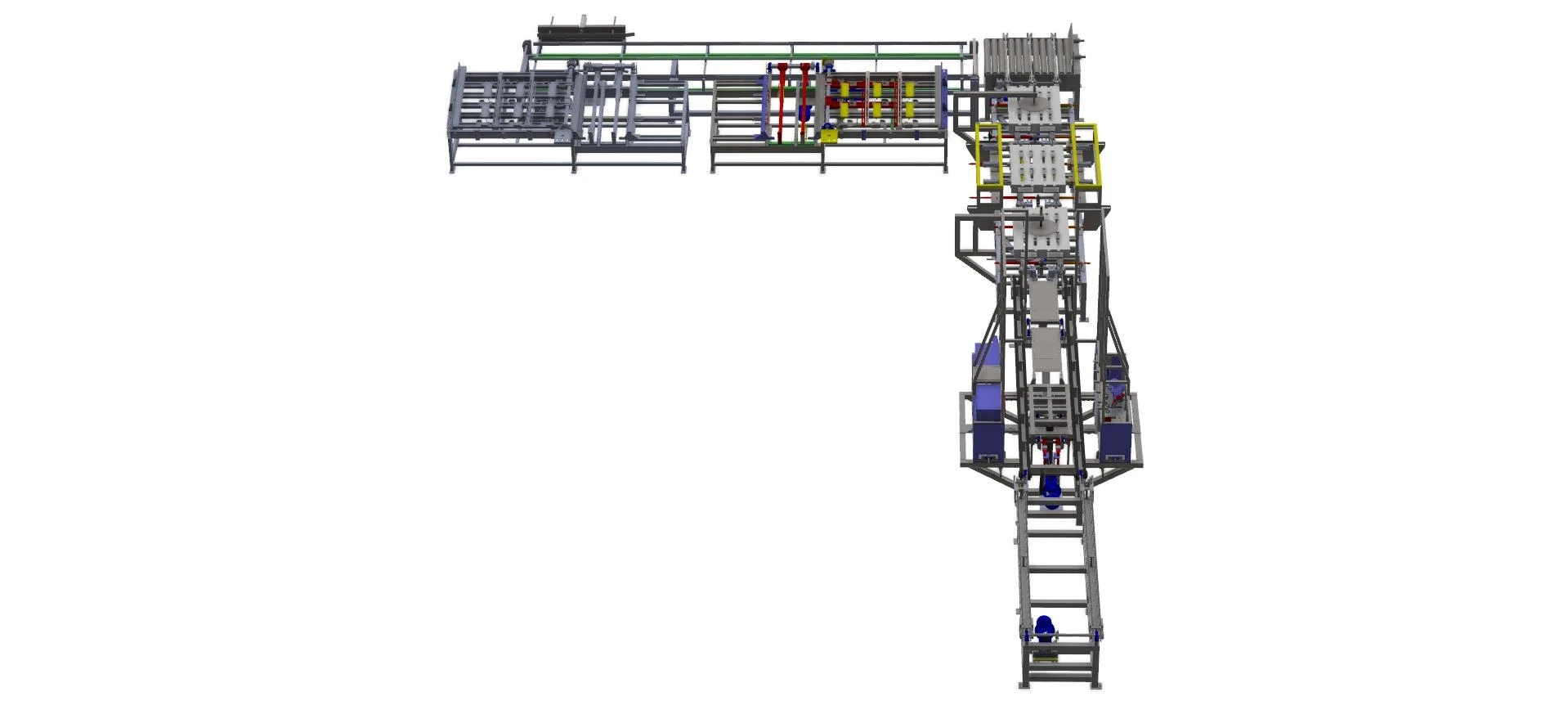

The semi-automatic pallet production line is a complete and modular solution developed for pallet manufacturers or sawmills seeking to increase their production capacity with reliability, flexibility and controlled investment. This line combines industrial technology with operational simplicity, enabling the sequential assembly of wooden pallets with high repeatability and dimensional consistency.

The line’s structure is designed to adapt to different layouts and production scales. It consists of several interconnected modules that can be adjusted to each client’s reality, whether in terms of available space, type of pallet to be produced, or desired production rate. This modular approach also allows the line to be installed in stages, facilitating progressive investment and future expansion.

Technical Composition of the Line:- Two double nailing tables for high-productivity assembly of both sides of the pallet.

- Conveyor with centering system to ensure correct positioning of pallets between modules.

- Quarter-turn conveyor to smoothly redirect the pallet to the next operation.

- Marking station with six marking heads, ready for branding logos, certifications (such as EPAL), codes or other identification marks on the pallets.

- Pallet turner with automatic stacker, allowing the stacking of finished units with or without corner trimming.

- Receiving conveyor to collect the stacked pallets, ready for dispatch.

- Electrical cabinet with PLC and automation system, providing centralised and secure control of the entire line.

The line can be delivered as a complete solution or acquired by modules, depending on the needs and growth strategy of each client. Customisation includes layout configuration, dimensions, additional features and integration with existing systems.

Manufactured by Irmach and marketed under the Bartly brand, the semi-automatic pallet production line is the ideal choice for companies looking to scale their production with robustness, intelligence and adaptability.