Description

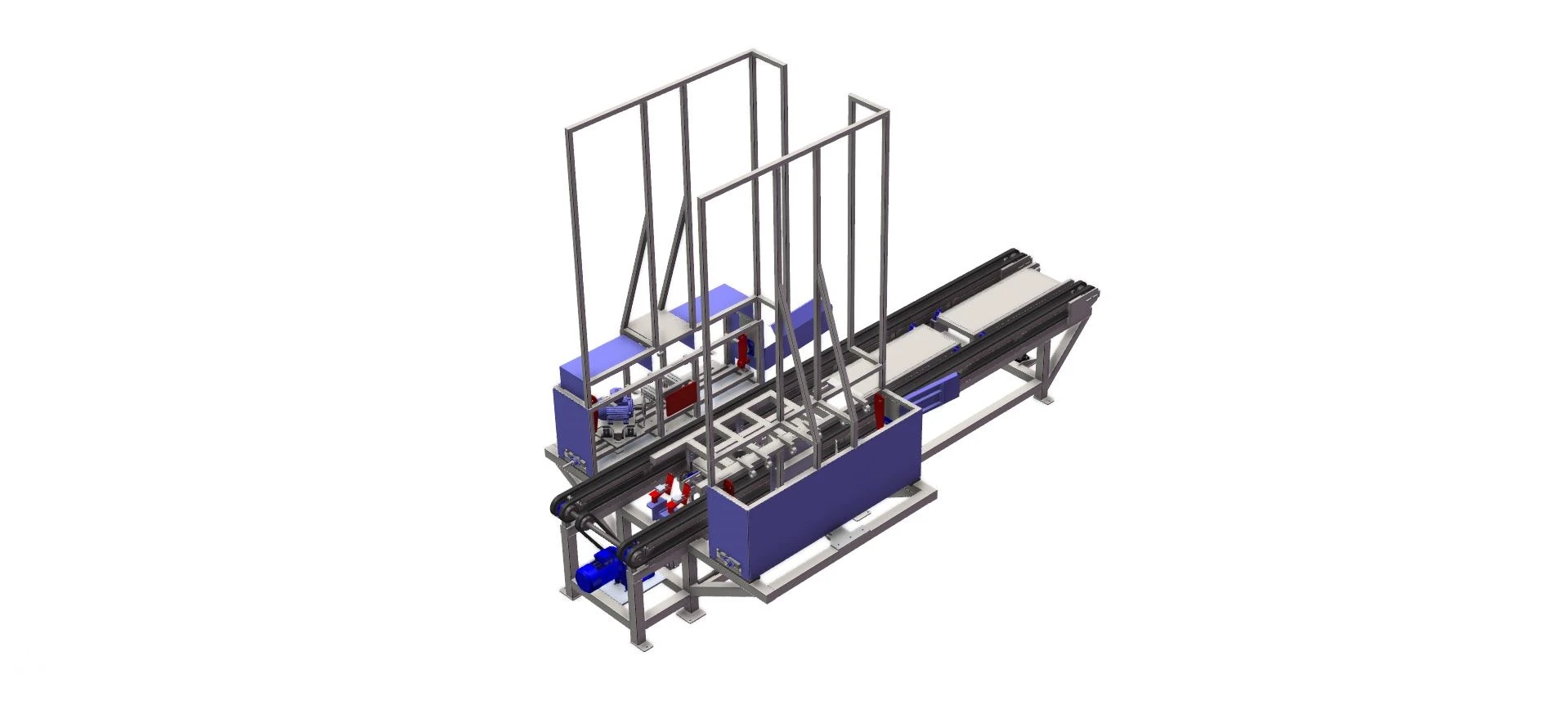

The automatic pallet stacker is an essential auxiliary machine in automated production lines, designed to carry out the continuous and controlled stacking of finished wooden pallets. Its function is to optimise handling, organisation, and preparation of units for storage or dispatch.

The equipment operates through a hydraulic platform that ensures precise lifting and positioning of the pallets during stacking. The system allows stacking with or without interlocking, depending on the type of pallet produced and the logistical requirements of the facility. The entire operation is managed by an independent control unit, providing autonomous and reliable functionality.

The height of the pallet stacks is adjustable according to the specific needs of the client, allowing full adaptation to internal processes and layout configurations. The stacker can also be optionally equipped with a corner-cutting system, ensuring a clean and standardised finish — particularly important for certain commercial or industrial applications.

Each stacker is custom-designed by Irmach’s technical team, taking into account operational parameters, integration with the rest of the production line, and available space. The robust construction, precise control, and ease of use make this equipment a reliable and efficient solution adapted to the demands of modern industry.

Manufactured by Irmach and marketed under the Bartly brand, the automatic pallet stacker is the ideal choice for companies seeking to automate and simplify the final stage of pallet production with safety, consistency, and high productivity.